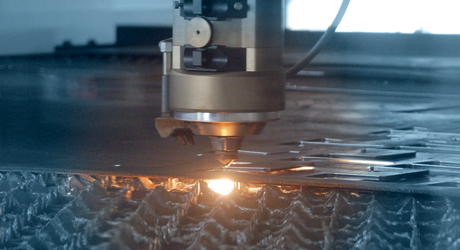

Laser Cutting

Specification

Capacity = 3m(W) X 6.5m(L)

Mild Steel = 25mm (thickness)

Stainless Steel = 20mm (thickness)

Aluminium = 12mm (thickness)

Advantages

The advantages of laser cutting are well established in the metal working industry. Aside from speed and accuracy, lasers produce the cleanest, smoothest edges and they do it cost efectively with high repeatability.

Waterjet Cutting

Specification

Table Size = 2m(W) X 7m(L)

Max. Pressure = 87,000 PSI (6,000 BAR)

Thickness up to 200mm

Material Applicable

Stainless Steel, Mild Steel, Aluminium, Copper, Inconel, Titanum, Tungsten, Carbide, Glass, Fiber Glass, Magnesium, Silica, Marble, Granite.

Advantages

Cold cutting which will not cause thermo and expansion on material.

Perfect finishing best for welding.

Suitable for customize component.

Bending

Specification

Pressing Force = 1,700kN

Working Length = 4,000mm

** With High Precision Patended LVD Easy Form Laser Automatic Angle Correction.

Plasma Cutting

Specification

Capacity = 2m(W) X 6.1m(L)

Thickness = 3mm - 100mm

Shearing

Specification

Maximum Thickeness

Mild Steel = 6.35mm

Stainless Steel = 4.00mm

Maximum Cutting Length = 4,000mm

Polishing

Specification

4B & Hairline Finish on Stainless Steel Sheet

Size = 1,219mm X 6,096mm

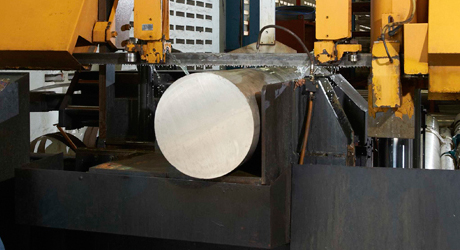

Bandsaw

Specification

Size = 3mm OD - 800mm OD

X 1,000mm (W) max